There are two methods available for manufacturing acrylic.

It is possible to find extruded (XT) acrylic and cast (GS) acrylic. Each option provides unique properties. Both extruded and cast acrylic adapts quite well to laser technology, and they are both ideals for laser processing purposes. It is important to learn more about engraving or cutting acrylic to ensure the best possible results are achieved. Keep reading to learn more about these.

While choosing the right laser cutter is important, and something boss lasers reviews can help with, learning how to use it properly is also important. Keep reading to learn tips for engraving and cutting acrylic here.

1. Laser Power Level

The necessary power level for the laser to cut acrylic or engrave it depends on the thickness of the material and the desired level of productivity. For a more productive work method, it is a good idea to use a laser power of, at a minimum, 60 watts. A good rule to follow is that for every millimeter of the acrylic sheet thickness, it is necessary to use 10 watts of laser power. This must be done to ensure a higher quality cut or engraving.

2. Using the Right Lens

Choosing the right lens is essential when it comes to using a laser for engraving acrylic. A general rule is that the thicker the material is, the longer the lens's focal distance needs to be. Selecting the right lens can be difficult, but it is possible with the right information.

3. Adjust the Acrylic Interior's Focal Point

If a person works to create a homogeneous and even cut, it is necessary to adjust the focal point properly. Try to adjust the focal point to the acrylic's interior. This is especially important when the material is more than six millimeters thick.

Some guiding values can be used. Move the focus to about one-third of the material's thickness. So, for a six-millimeter acrylic, this would be the "z" value of -2 millimeters.

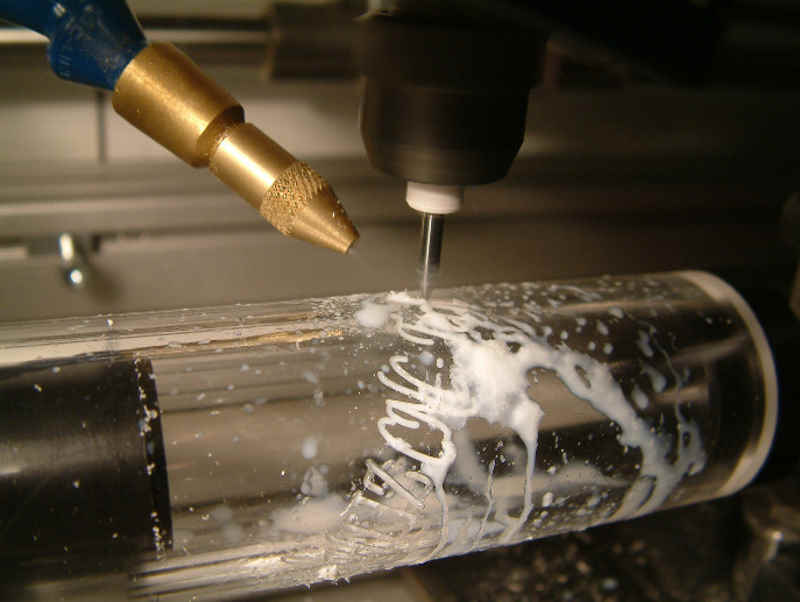

4. The Proper Nozzle Matters

When laser cutting acrylic, the nozzle with the bigger diameter needs to be used, and if controllable, it is possible to reduce the issues that may arise. If the nozzle diameter is too small, or if the total air pressure reaches levels that are too high, the results could be milky and dull on the edges because the material cools too quickly.

5. The Proper Table Selection

Choosing the right table is an important factor to consider when working to achieve better cutting and engraving processes when it comes to acrylic. There are several options to consider, based on the size of the application. It is a good idea to use an acrylic slat cutting table or an acrylic cutting grid table.

Finding the Right Engraving Machine Matters

When it comes to cutting or engraving acrylic of any type that is being used, there are more than a few factors to consider. Unfortunately, this can be easier said than done. However, with the tips and information above, it is possible to make the most of the chosen machine. Taking the time to learn how to use the machine chosen will pay off in the long run, so be sure to keep this in mind. Being informed is one of the best ways to ensure the desired results is achieved with the laser engraver or cutter that is used.