So you have a great idea for a product that you think would be a big hit in stores across the country, but you're not sure how to turn that idea into a prototype and eventually produce it on a mass scale?

Even if the concept-to-production process may seem overwhelming, the truth is that you don't have to be running a major corporation with a network of factories to turn your idea into a reality. The following are some essential steps you can go through to get your product ready for production!

1. Do your R&D.

This is a vital first step, and it's one that many skip. Does anyone else own a patent on this idea (You can make a preliminary search at the U.S. Patent and Trademark Office)? Do you know who is your target market? What materials, production methods, and expertise are required to produce your product? About how much will it cost to produce? Basically, you want to try to determine if your product idea is both feasible and marketable.

2. Protect your idea.

Once you've determined that no one else has come up with your idea, then you want to do what you can to protect it. First, make sure that you document everything that relates to your new product including what it is, how it works, what it is made of, and how you will produce and distribute it. You should also find a qualified patent attorney or other patent professional who is registered with the U.S. Patent and Trademark Office. This person will help you to craft your patent application once a suitable product or design prototype has been made. Finally, make sure that any outside parties who will be working with you in the design and production process sign a thorough confidentiality agreement. This document should also be looked over by a qualified hired professional.

3. Bring others on board.

That said, even if you are knowledgeable about your particular product or industry there will likely be many aspects of the product and/or production that lie beyond your area of expertise. It is vital that you seek out those people and services that can help you fill in those knowledge gaps. Some typical examples include a qualified attorney in business law, country-specific experts (for international production and/or distribution), and a product development specialist who can help you turn your idea into a physical prototype.

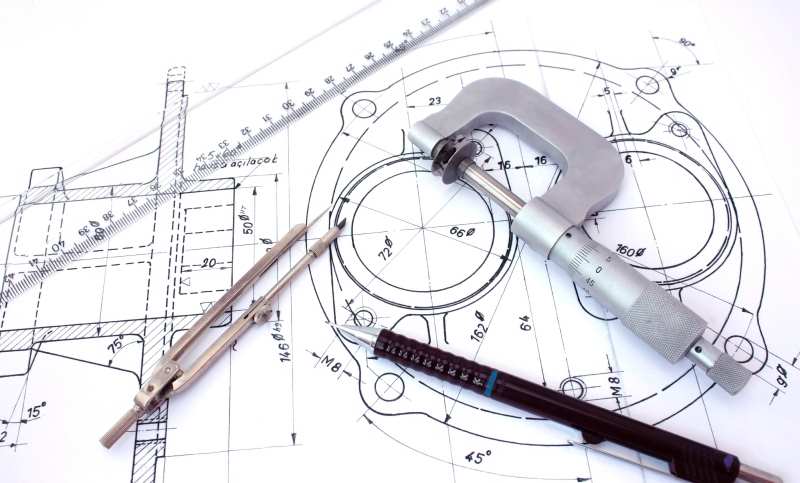

4. The specifics.

Have a collection of product drawings and other renderings and where possible even samples to build a concrete understanding of your planned product. To prevent misunderstandings the first thing you should do is to make a complete and thorough production specification sheet. If you are planning on sourcing from abroad, consider hiring a procurement specialist to help you with this step.

Make sure to include at least these four sections in your spec sheet:

- The desired dimensions

- The specific material(s) you want to use

- The packaging you envision for your product

- The different technologies that may be involved in the product

5. Where do you intend to produce?

Give some thought to where you would like to produce your product. This should include which country you plan on carrying out the manufacturing process and any relevant country-specific information, such as the legal environment, demographics, and other socio-economic factors.

If you intend to mass-produce, a long term sourcing relationship with a particular factory can be cost-saving in the long run. A qualified product development expert can offer you several quotations from different factories and can help you identify the best manufacturers in your field. Once you've narrowed down your search, make sure you do a diligent review of any factories you would like to work with. Factory audits and qualifications are very important for a smooth product development and manufacturing process.